Major Projects Undertaken By Us

Fabrication of Caisson Gate for Surya Dock of Naval Dockyard Vizag

This caisson gate measuring 23x15x6 Mtrs 320 Ton steel structure with 334 Tons Ballast weight is fabricated on the shore without docking facility. This was an achievement as there were apprehensions about the success of this project till the newly fabricated Caisson gate was tried in the dry dock for its purpose.

The project was done under IRS classification and certification. The modulars were fabricated at our works in Kakinada and transported to Yanam where the complete assembly was undertaken on shore alongside the Godavari River, which joins the sea. The fabrication was completed in record time frame of 12 months. The Gate was towed to Vizag by sea in Horizontal position. The Ballast made of Iron Bricks, Iron scrap billets and Cast Iron blocks totaling to 340 Tons was added manually and the gate was made vertical. Thereafter the complete ballast system piping and air system for de-ballasting was installed and the trials were conducted in Dry Dock. As the gate is required to be under saline environment the gate has been duly protected with adequate sacrificial anodes and underwater paint scheme The Fact that the trials of the gate to check the seating of the Caisson for the Dry dock was successful in the first instance, proved that structure was built with utmost quality standards and professionalism.

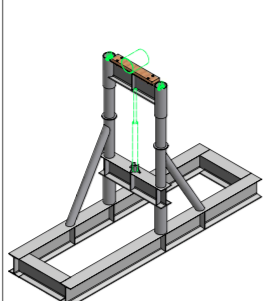

Keel Laying And Platform Erection

Vertical Sections And Bulkhead Erection

Final Stage Fabrication

Ready For Launching Into Water

Launching into Water

After Launching – Ready For Tow

Undertow into Docks

In Dry Dock for Final Finish

Caisson Gate in Operation

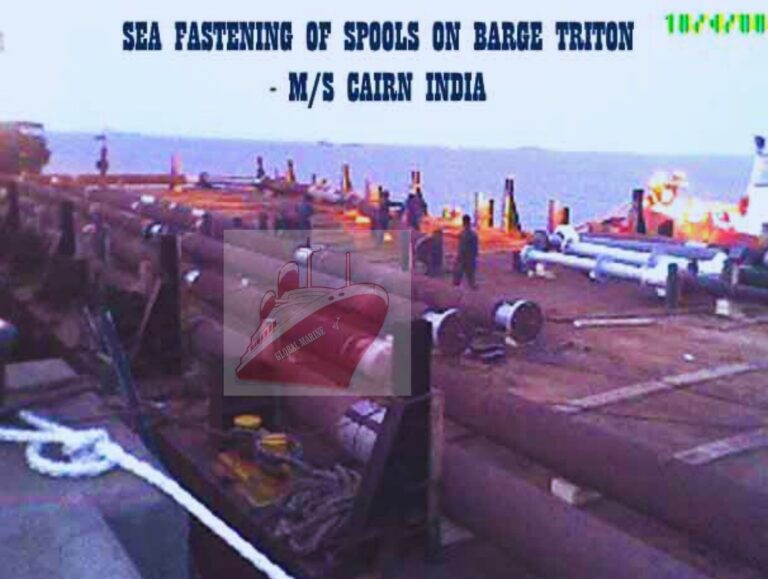

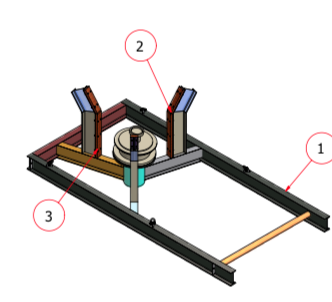

Sea Fastening Activity

Sea fastening for all the equipment was undertaken for loading and sea fastening of spools on Barge with necessary arrangements for Cairn India Ltd, , Technip France and UK for their Sub sea activities and, Sea fastening of Christmas Tree for RIL and sea fastening of diving equipment for Deltek and Adsun Offshore.

The major activity has been the sea fastening of spools on Barge Triton for Cairn India Ltd. The activity involved.

- The Backup Stanchions were installed by fabricating from ISMB 250 beams and wooden fenders were provided for each stanchion on the Barge. Base Plate of 20mm Plate was used for the footing and welded to the deck

- Wooden Dunnage was provided on the Barge as sleepers for each lot of spools being secured.

- On Placement of the spools on the Barge, the lashings were arranged

- Each lashing consist of 16mm Usha Martin Make wire rope, wire rope clamps and thimbles, Sea linker make 3.75, 4.75, 6.5 and 8 Ton Shackles as er the load requirement and sea linkers make 12” and 18” Turn Buckles.

Sea Fastening for Technip :

The sea fastening activity was undertaken for M/S Technip France for their 3 campaigns with RIL during the years 2007 to 2011. The activity involved, mobilization of manpower and working on the vessels on 24×7 basis round the clock when the vessels arrived for loading/unloading sub sea structures. We had undertaken sea fastening for their wet parking frames, hub transportation stands, jumper stands etc.,

The main activity for sea fastening involved

- Pre fabrication of gussets for the main equipment at work shop.

- Pre fabrication of shims in Work shop

- Preparation of lashing material for sea fastening

- The lashing consisted of Approx 21 Mtr of wire rope, 04 Nos turn buckles, 8 Nos shackles of 3.75/4.75 Ton capacity depending on the tonnage of equipment and required number of thimbles and wire rope clamps.

- One end of the lashing was fastened to the equipment and the other end was fastened to the deck or nearest available securing point.

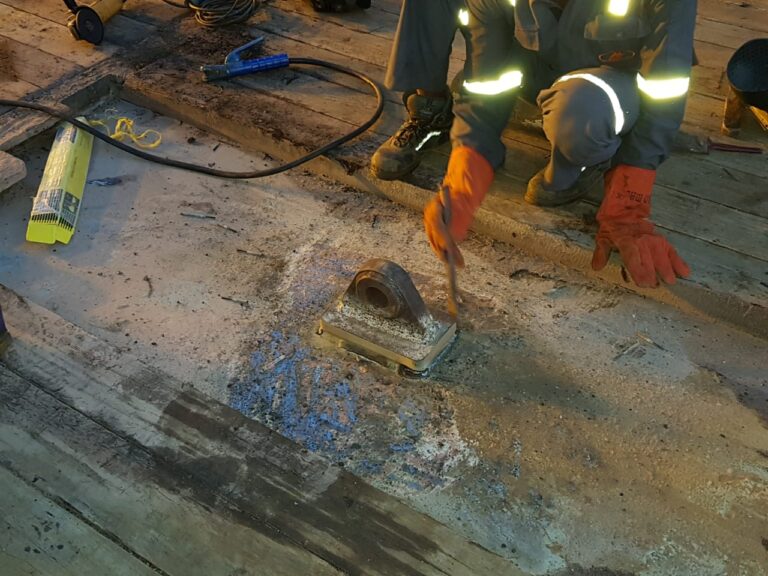

- The Pad plates were of 100x 100 mm size and were fabricated from 14mm MS Plate. The Pad plates were welded on to the deck after removal of wooden sheeting from the deck.

- Test certificates/material certificates were provided for wire ropes. Shackles and Turn Buckles,

Sea Fastening for Diving Equipment for Cairn India Ltd.

We have been undertaking the sea fastening activity for diving operations for last 15 to 20 years for our client Cairn India When ever the diving operations are planned, the sea fastening of the diving equipment like compressors, cylinder racks, Diving containers, A brackets, etc., were undertake by us. The sea fastening was undertaken on both Temporary fastening basis as well Permanent sea fastening basis.

The temporary sea fastening is undertaken using wire ropes and lashings and secured to ships bollards . The permanent sea fastening was undertaken using gussets and eye pads welded to the deck and all the lashings secured to the eye pads. These permanent lashings are meant for securing of the equipment for longer durations on the vessel and the lashings should withstand the rough sea states including stormy conditions.

Welding of Eye Pad on Deck

Mudplant Modification

The complete Mud plant of M/S RIL has been modified and relocated to new site in Port premises. A total of 29 Mud tanks have been refurbished and new pipelines of approx 1200 mts of different dia have been installed. The complete system was tried and proved to the entire satisfaction of M/S RIL. The work was undertaken during the year 2011-12.

The gratings and walkways have also been renewed

Major Works Carried Out For M/S Technip France

We had been associated with Techno France and Technip UK in connection with fabrication of Sub sea structures and related works including sea fastening activity for all their vessels for their Offshore movements. We were associated with them during the 3 campaigns they worked for RIL from year 2007 to 2012 and we had been the most favored service provider for them.

Broadly we had undertaken following fabrication works

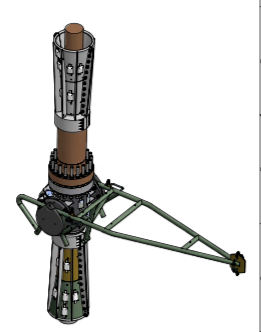

- Wet Parking Frames

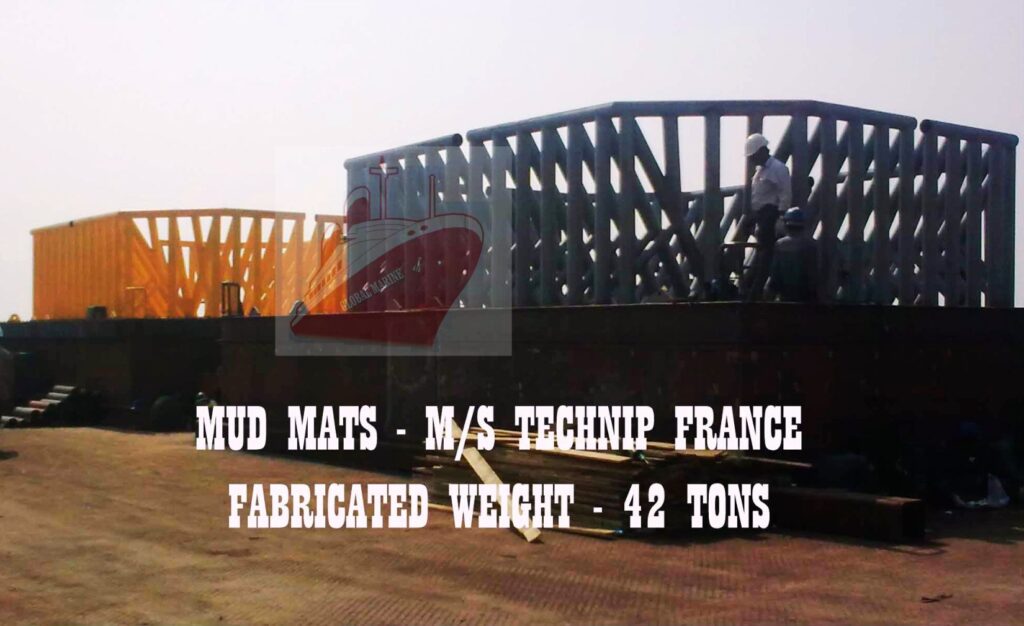

- Mud Mats

- Jumper stands

- PLET Stands

- Flying Leads

- Spreader Bars

- Container Grillage

- FTH Yokes

- Tether Clamps

- Hold Shoes

- VCM Support stands

- Hang Off collars

The following major works need to be mentioned to understand the type of works undertaken.

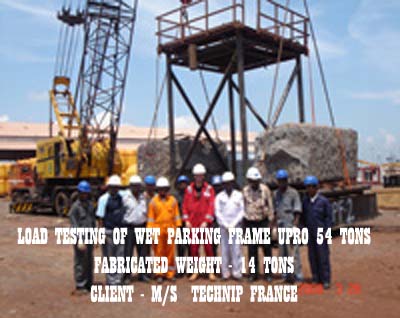

- Wet Parking Frames – We have fabricated 06 nos wet parking frames during the years 2008 & 2009. The wet parking frames have been fabricated of various designs. We have also carried out load testing of one of the wet parking frames to a test load of 55 Tons after fabrication to ascertain our quality. The load testing for such huge load was undertaken using Granite blocks and placing them on the frame platform.

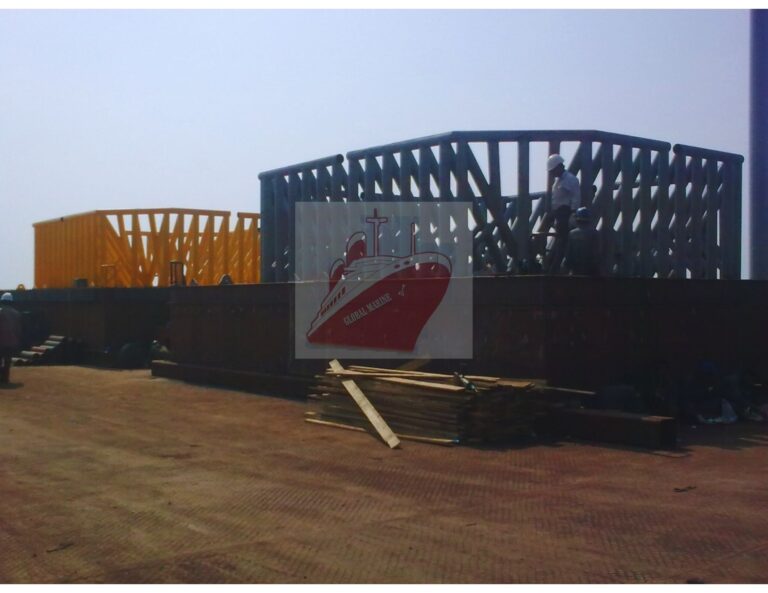

2. Mud Mats : We have fabricated 02 Nos Mud Mats for their sub sea requirement. We have fabricated this Mud Mat as per the design provided by M/S Technip France in 02 pieces using Scheduled pipes and rubber fenders specially molded through Rubber manufacturers. These 02 sections each weighing 20 Tons (Approx) have been shifted to Port area alongside the jetty and joined together by welding and clamping.

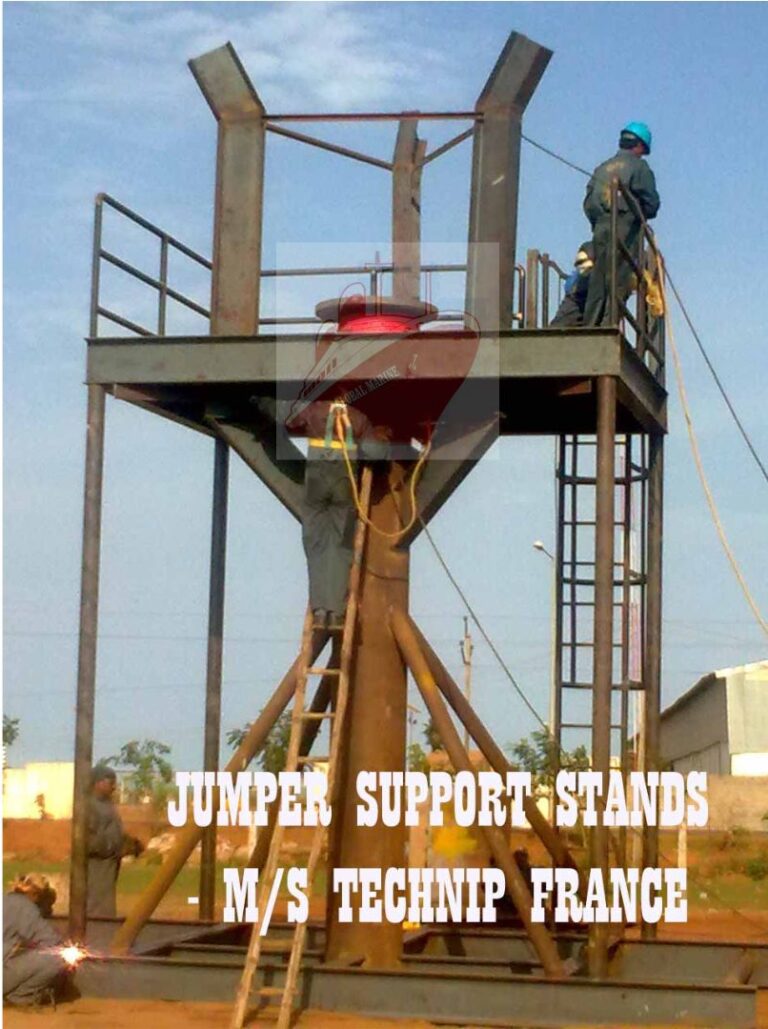

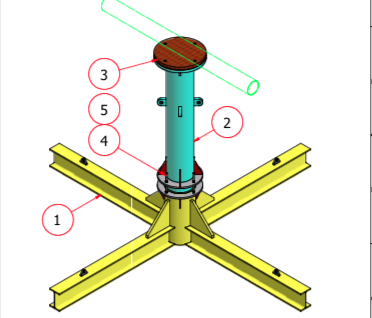

3. We have also fabricated Jumper support stands and Guide Frames for sub Sea systems for Technip France.

Jumper Support Stand

Guide Frames

Jumper Onshore Stand

Intermediate Stand

Plet Side Hub Support

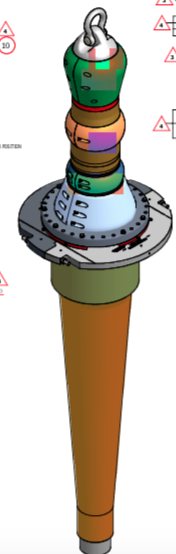

Tether Clamp