Load Testing of Lifting Appliances

All the lifting appliances fabricated new, like cargo baskets, pallet racks, pallets, spreader bars etc., undergo Load test. The Test load applied is dependent on the WLL and generally the test load applied is double the WLL. As the WLL increase, the multiplying factor decreases and even reduces to 1.1 times of the load if higher WLL like 100 tons and above.

The load testing is undertaken by a competent person as per Dock workers (Safety, health and welfare Board) Regulations 1990 as per regulations 47(1) and 51(2)

The loads are generally paced inside the cargo basket if it accommodates the required dead weights or under slung if the loads are more and place inside or on the appliance is not sufficient.

Prior to applying the loads, the eye pads are tested for MPI. If MPI is OK, then the load test is carried out. The test load is applied for approximately 5 to 10 minutes. Prolonged loading with test load is not advisable as there is tendency for deformity occurrence at the joints. On completion of load test, MPI is again is conducted.

We had fabricated many lifting appliances including spreader bars. We had also conducted load test for A Bracket frame for offshore vessel engaged in maintenance of SBM and we had conducted Load test of A Bracket frame using Water bags as load cells.

Load Testing of a Bracket with Water Bags as Load

Load Test with Underslung Dead Weights

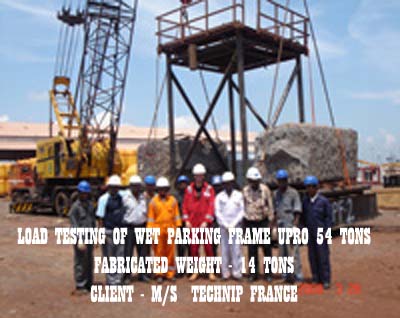

Load Testing of Wet Parking Frame Upto 54 Tons

Fabrication and Load Testing of Spreader Bar

Load Test of Cradle with Dead Weights Placed Inside

Load Test of 60 ft. Baskets using Self Weight, Dead Weights and Additional Basket as Load

Load Testing of Lifting Cradle

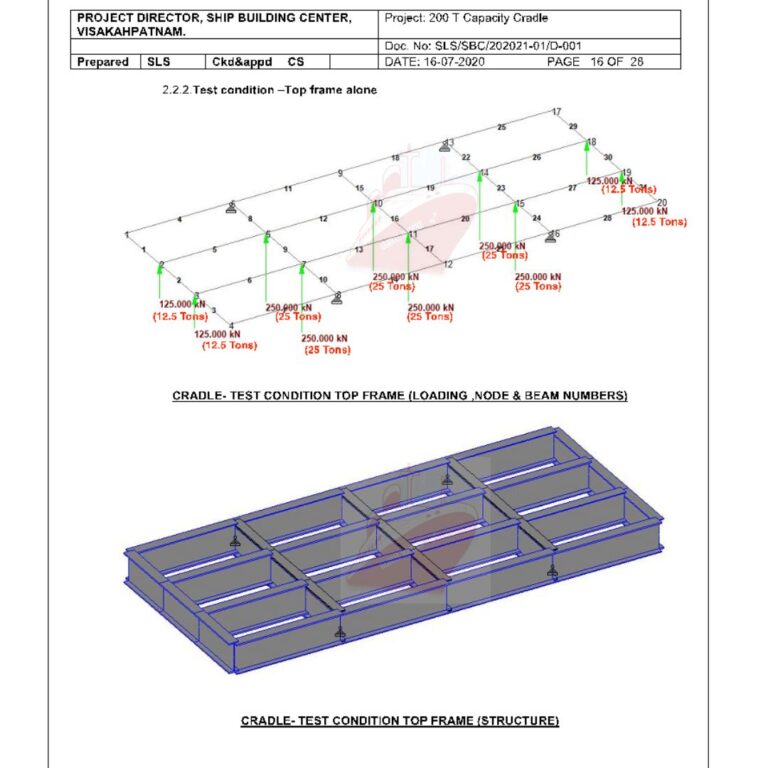

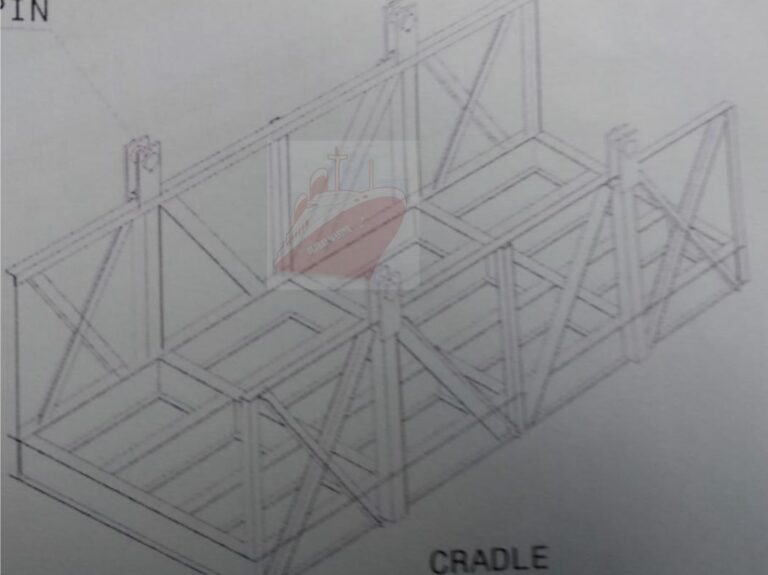

We have fabricated a lifting cradle for testing of EOT crane for a shipyard. The cradle is designed for loading 200 Tons of test load. In order to test this cradle, a test load of 220 Tons is require to be loaded into the cradle. However, the space available is not sufficient.

We have devised method indigenously to over this problem and planned for testing by using hydraulics system.

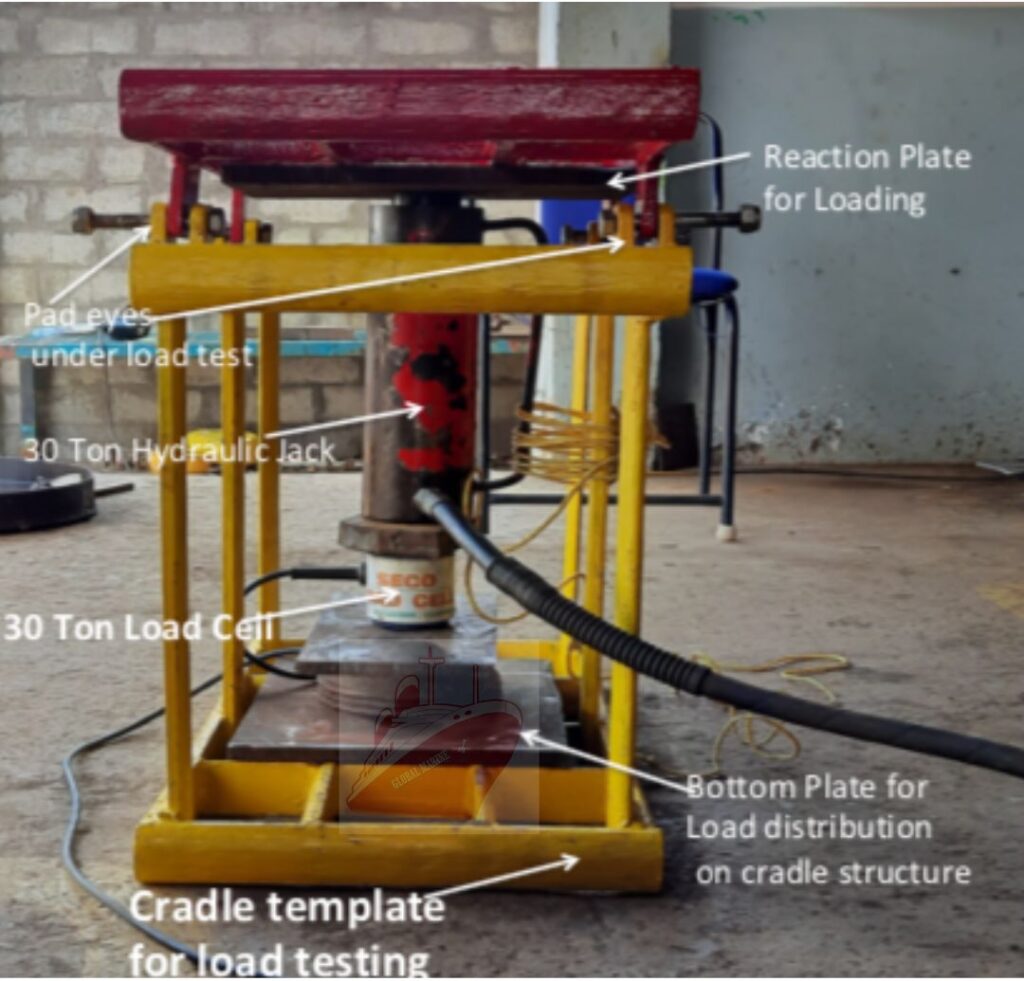

A prototype was devised in the workshop to ensure that the model works. We have devised a testing device with 30 tons loading system with reaction load on to the frame

On success of prototype, we have done the design validation of the loading pattern. As per design validation, we have utilized 30 ton hydraulic jacks and 25 ton load cells placed as per the design calculations. The Load test was carried out with the arrangement of load cells and Hydraulic jacks and the test was successful.

Cradle for Load Testing