Offshore Fabrication Activities

Modifications to Burner Boom Structure of Rig Hercules 31- M/S Cairn Energy India Pvt Ltd.

This work was undertaken during the year 2007 and involved complete modification to jack house structure of the rig Hercules H-31. As the work was required to be undertaken while the rig was in operation, complete safety and utmost care during the work for the structure and the men had to be ensured. The complete modification to the structure included strengthening of the jack house and modification to the burner boom. The burner boom, which was damaged, was shifted on shore to jetty, where the complete structure of the burner boom

was renovated and the heavy machining for bushes made of Gun metal and En steels for the pins of 200mm dia and 350mm dia was undertaken in our machine shop. The support brackets for the booms were fabricated and welded to the burner boom support structure. New walk way was also fabricated for the booms. The fabrication of Approx. 40 tons of Steel was carried out with Third Party certification of RT and MPI. On completion of the modification, the complete burner boom was load tested up to 22 tons with SWL of 11 Tons.

Fabrication of Diver Platforms for Cairn India Ltd.

We have fabricated diving platform for 3 offshore Platforms for Cairn India. The installation of these diving platforms was not included. The platforms were fabricated from ISMB and each Diver platform weighed 6200 Kgs. The work was undertaken as per drawings given. The scope also included supply of galvanized Grating and handrails as per the requirement mentioned in the drawing. On completion of the work the complete platform with railings was load tested.

Dual PCV Piping for Cairn India Offshore platforms

Dual PCVs with piping were fabricated and installed for 5 platforms of Cairn India Ltd (Vedanta Limited). The work involved fabrication of piping as per isometrics taken from the platform as per the clients’ requirement, after fabrication of the piping, 100% Radiography of all joints was undertaken and Hydro test carried out. On completion the complete system was installed and Hydro test conducted again to ascertain all the system is tested.

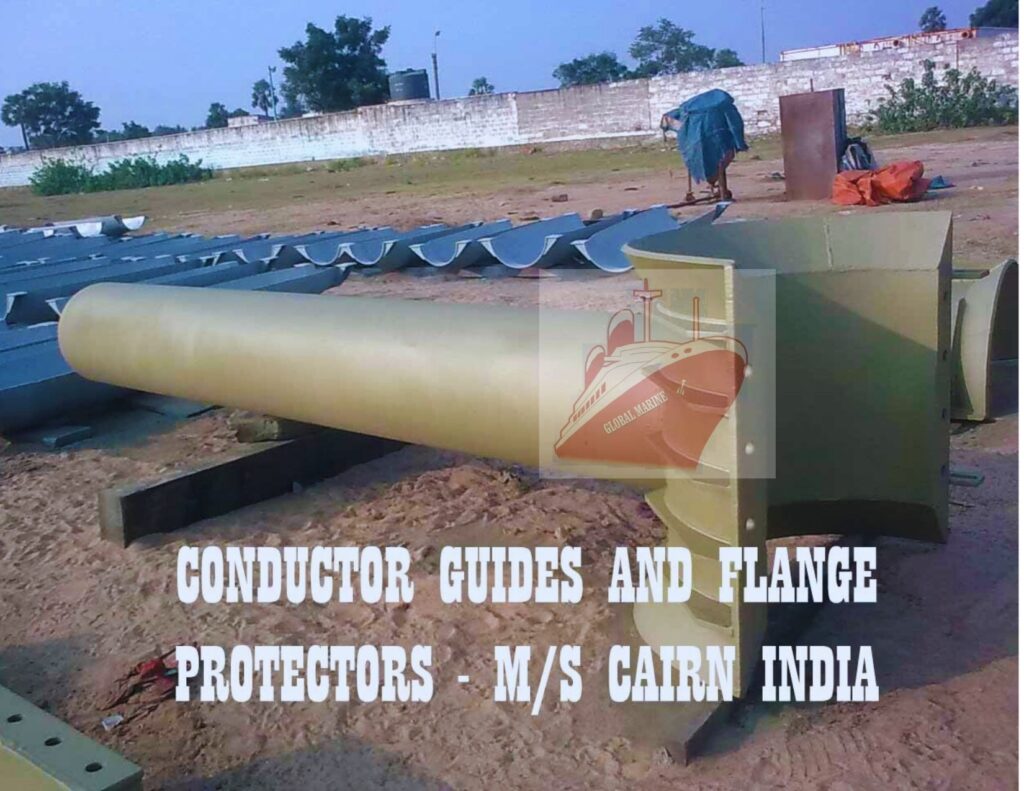

Modification of Offshore Platform – M/S Cairn Energy India Pvt Ltd.

The modification was carried out to accommodate additional conductor for the platform and involved fabrication of Guide plates of 20mm MDS Plates for all three levels of the platform (Jacket level, Cellar Level and Top Deck level). The fabrication also involved processing 25mm thick plate in to 610 dia pipe of 1.2mtrs length. The Support structure for jacket level fabricated using 273mm dia schedule 120 pipes and Support structure with ISMB 300 and ISMB 250.

We had to use Pre Fabricated H Beam of 700×400 with 20 mm and 16mm plate, as the same are not available standard sizes and the same to be fabricated at our works. The Top-level platform for extended portion with ISMB 125 including gratings and hand railings were part of the scope of work undertaken by us.

Platform Modification For Cairn India

The Piping modification and platform modification was undertaken during the year 2022 for Cairn India Ltd (Vedanta Limited). The piping modification involved fabrication of high-pressure piping of 3 inch, 4 inch 6 inch and 8 inch piping of schedule 80. After completion of fabrication of the complete spool on shore, the piping was pressure tested and Radiography done for 100% joints. Thereafter the complete spools were installed on Platform and Hydro test conducted.

The casing guides were also modified for two platforms at the boat landing area.

Overboard scaffolding was erected on the platform to undertake overhead jobs for piping

ONGC Platform Jobs

During the year 2018, we have undertaken Fabrication and hook up for modification jobs on unmanned platforms – GS-15-4 AND GS- 15-1 for put on production of gas injection wells GS-15-13A & GS-12 Z.

The work involved

- Fabrication and hookup of 2” spool between # GS-15-12 Z well head “C” section and existing 2” Gas Injection header line.

- Fabrication and hookup of 4” spool between 6” Pig launcher/ 4” well fluid line of GS-23-1 and existing Gas injection line on platform GS-15-4. (For converting existing well fluid line as Gas injection line after Pigging job) and create interconnection between new 4” GI line and existing instrument and utility gas line with necessary isolation valve and NRVs.

- Fabrication and hookup of 4”spool between GS -23-1 well fluid line (4”) and GS-15-4 platform well fluid line (6”).

- Reversing 6” 1500# NRV between GS-15-1 well fluid line (8”) and GS-15-4 well fluid line (6”).

- Shifting of 11 nos. of PSVs (Small sized ranging from 1” to 2” inlet flanged) from OOT to the platforms GS 15-4 and fixing the same on the platforms, which are calibrated

- Fabrication and hookup of 2” spool between # GS-15-13A well head “C” section and existing 2” Gas